Sándor Ambrus

|

|

|

|

|

The ZIU-5 trolleybus |

|

Sándor Ambrus

|

|

|

The ZIU-5 type trolleybus was after the MTB-82

series the next, which was bought from the Sowiet Union. As the MTB 82

became a standard type in Budapest (since the

IK-60T was built after the plans of

the MTBs); the ZIU-5 also became a basic type of tht BKV (Budapest

Transportation Company). Here also not the very construction was basic,

but it was the first of a family, which had similar electric equipment

- the ZIU-9 and the IK-280.T1 (100 series) are very similar electrically to

the ZIU-5.

|

|

|

|

|

Sándor Ambrus

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The electric circuit of the ZIU-5 is in many aspect the automatic version of the MTB-82's equippment. Both types have double coiled motors: with a main circuit (serially coupled to the rotating part) and a separate outer exciting circuit. Also the principle of the coupling is similar, both in acceleration and rheostatic brake. The main difference is, that there are less contactors in the ZIU-5, because the varying of the resistors are mainly done by the automatic starter device.

This brought some other changes, mainly because the starter

works only "one way": it is not able to reopen the electric circuit.

|

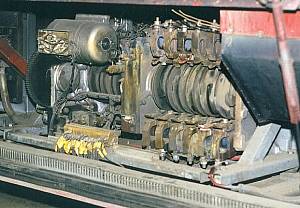

On the image is the starter of one of the IK-280 trolleybuses in Debercen (401-404), which is fitted with ZIU-9 equippment. The starter of the ZIU-5 was almost like this: on the left there is the motor, on its right the cylinder and the coupling elements are visible. |

Dániel Szigeti

|

Since the starter cannot get the resistors out of the circut, there

are contactors to do so. The manouvre contactor LK3 can insert a large

resistor in the main circuit and the line contactors LK1 and LK2

shut the main circuit completely out of the poles. At the end of the

acceleration

there is this two step of closing the circuit before the accelerator

turns back the cylinder into the initial position.

At the beginning of the acceleration this happens opposite way:

first the line contactors turn on the motor, then the LK3 gets out of

the circuit the large resistor in less then a second. This is the manouvre

stage: it is possible to go like this (with all the resistor coupled by

the starter inside the main circuit) in low speed.

|

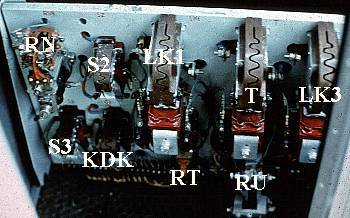

The LK1 line- , T brake-, LK3 maneuvre contactors; the S2, S3 exciting circuit contactors, and the KDK compressor regulating contactor are visible. Also there are some relays: the zero voltage relay (RN), the maximal relay (RT) and the acceleration relay (RU) is there. The rest is covered by the wall of the driver's cabin. |

|

The speed of the starter is regulated by the acceleration relay (RU), which stops the cylinder if the current is higher than a certain threshold. This threshold is 250 A in the second position of the accelerator pedal, and it is lower at the first position. In case there are some irregularities in the level of the current, first the maximal relay, then the fuse switch (which is above the head of the driver) can break off the circuit.

At the end of the acceleration, the R accelerator contactor short

circuits all the resistors (and also with this the outer excitation is decreased).

This happens around the speed of 30 km/h. After the shunt

cascades come into the play, regulated also by the starter. Hereafter

the speed of 60-80 km/h was possible to reach. There is three shunt

possibility according to the accelerator pedal position.

|

|

The rotating part of the motor is between JA-JAJA, the

main circuit's exciting coil is at K-KK, and the outer

exciting coil is at S-SS sign.

|

The acceleration of the ZIUs are not very smooth: the beginning of the starter's operation, the coupling of the R contactors and the shunt cascades make a considerable kick to the car. However the articulated 100 series with ZIU equippment were much better: the larger weight of these trolleybuses nicely decreased the strength of these kicks, without considerably loosing the speed and accelerating power.

There is no possibility of recuperating brake on the ZIUs, since the

shunts are regulated also with the starter. For decreasing the speed there is the

rheostatic brake.

By pressing the brake pedal all the main circuit will be out of

voltage

by releasing the line contactors (so during the brake the starter can go

back). However the brake contactor T makes the rotating part coupled

on the resistor of the LK3 (which is also released). The S

exciting-circuit contactors regulate the current of the braking in two stage:

this gives a very smooth and not exremely powerful decrease of speed.

During the brake pedal is pressed, the trolleybus uses a small current

to supply the exciting magnets: if there is a dead section (e.g. tram

crossing), then the rheostatic brake becomes ineffective. By pressing

the pedal further down, the pressure air brake could always fully stop

the vehicle.

|

The ZIU-5 had the old iron trolleys; if it got loose it could make more serious damage as todays' aluminum trolleys. Also the older trolleys were just painted, but had no insulating cover: so the side of the trolley could cause an electric shortcut stalling in the overhead wire-system. |

|

|

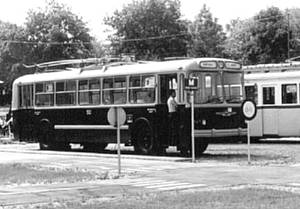

On the picture is the 521 at the entry of Pongrác depot, in the '70s. The radio-filters are visible on the roof: to the 600 V trolley belonged twice as large as to the 0 V. These were made of coils and capacitors. |

|

Electric devices operating from accumulator:

The ZIU-5 had interestingly two low-voltage circuit: 12 V and 24 V. The microphone (installed posteriorly), the turn signals, the front lights, the speedometer and the windscreen wiper operated from 12 V, the rest from 24 V. The 24 V circuit was joint to a dynamo (with own motor running constantly) to charge the accumulator, the 12 V was probably simply branching from the accumulator cells. Later the 12 V devices were using 24 V with a resistor in the circuit.

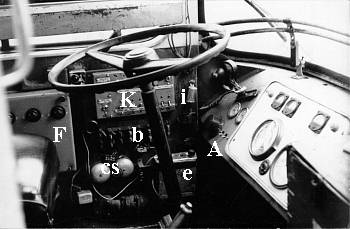

Let's have a look in the driver's cabin:

Rudolf Lakos

|

|

|

Heating switch (F), 17 low-voltage switches (K), windscreen wiper (A), 9 low-voltage fuse (b), emergency- and no-voltage bells (cs), amplifier (e). Behind the heating switches was the switch of the dynamo. These parts are better hidden on ZIU-9. |

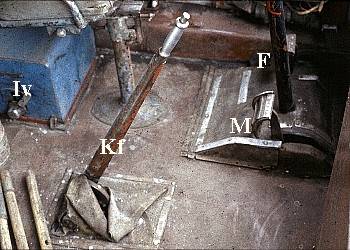

direction selecter (Iv), handbrake (Kf), accelerator (M), brake (F). The box of the direction selecter contains the also the KVP-22 type controlling cylinder: this is mechanically joint to the pedals. The arm of the direction selecter was removeable, this was supposed to be taken by the driver. |

The doors ran with 24 V motors. The switches of the doors

had three stages: in the middle stage it was possible to turn off the

motor. This was neccessary when the door was shutting someone: the

motors could quite heavily press the passenger, and if the doors did not

go to the end, the motor could burn down.

A get off requesting signal was only at the rear door.

|

Rudolf Lakos

|

|

The cover of the seats was typical russian: the soft coushioning compensated the hard suspension of the trolleybus. It was a usual view as the passengers bounced together on the seats as the vehicle went through a bump on the road. At the back was the conductor's seat, which was never used in Budapest, since by the time the trolleybuses went into the service, there was no conductor job. |

|

|

Ferenc Szántó

|

|

|

|

Blickpunkt Strassenbahn

|

Blickpunkt Strassenbahn

|

|

|

|