|

|

GVM - IK-280 trolleybuses |

|

|

|

|

|

|

|

|

|

|

|

GVM is an abbreviation: meaning Ganz Villamossági Művek (Ganz Electric Works). However, hereafter I will use it as it is done by BKV - referring to the IK-280.93 type articulated trolleybus fitted with chopper control electronics, although there were other constructions of the Ganz factory.

The Ganz Electric Works built two prototype chopper control trolleybuses by 1980, for testing and demonstration. The first vehicle was exhibited on the Budapest International Fair after its trial runs, then it was taken to Leipzig (East-Germany) again for the Autumn International Exposition. Then it was pulled to Weimar, where (between September and November of 1980) it made succesful testruns. In the following year this trolleybus toured Bulgaria, on the expo of Plovdiv, then it made again demonstrational runs in Sofia.The first IK-280 trolleybus prototype of Ganz (IK-280.T6)

This vehicle had full red liveries, and was fitted with flapping doors, which was unusal at the time. The chassis and the body was similar to the standard Ikarus buses, with minor changes because of the electric parts. Its electronics was significally different from the later series', it was resembling mostly to the BBC prototypes. The simplified plan of the electric circuit can be found here. The most important difference is the lack of the rheostatic brake, instead a separate Eddy-current brake was installed on the motor axle. The trolleybus was fitted with a TK 101 type 150 kW motor, and a 39 kW petrol aggregate being able to run on wireless sections. Also a mechanical trolley puller device was installed.

In 1982, the vehicle was brought to Szeged, where on 19th July, 1984 it was taken in the fleet with the number T6-281. It was in service until the end of the '80s; around 1990 it was hit by a lightning, damaging its electrical parts severely. For a few years the trolleybus was still stored in the depot, until it was scrapped officially in 31st March 1996, and dismantled.

The second prototype GVM was produced for Izmir (Turkey) still in 1980. This one had orange color with a white stripe on the side. After the trial runs in Budapest, the trolleybus was also on tour in Ankara too. Then it was taken back to Budapest, and possibly after some more runs in Budapest in 1982 (?), this vehicle was also supposed to go to Szeged (with the proposed fleet number T5-281). However, instead it went back to the Ganz factory, and was used for experiments of the chopper control in 1984/85 (the other testcari of the factory was the second BBC prototype). After the works, the non-functioning vehicle was taken to Damjanich depot.The second GVM prototype trolleybus (IK-280.T6/1)

In 1990, the empty body was reused by the Obus Ltd., it was fitted with a ZIU-9 electrics (from the parts of DKV 9-310, which had an accident). Indeed on 19th March 1990 this articulated trolleybus was taken to the fleet of Debrecen with the number 400, being the first articulated trolleybus in the East-Hungarian town. (Four similar trolleybuses followed as it is described here.) However the car still possessed its prototype being, many parts were impossible to mend, and its cabels were also a mess. This was the reason, why it was on 25th January 2000 scrapped and taken apart.

The original electrics of the second prototype was similar to the first, except iti already had a rheostatic brake with resistors (without recuperation) regulated by the chopper. So the heavy and unreliable Eddy-current brake device was spared. This trolleybus was also fitted with a 39 kW petrol-aggregate.

The first order of the GVM trolleybuses came from East-Germany and Bulgaria. In East-Germany, the city of Potsdam, Weimar, Eberswalde and Hoyerswerda obtained articulated Ikarus trolleybuses.GVM trolleybuses in East-Germany (IK-280.93)

In this country, by the '70s the whole trolleybus fleet became obsolescent, typically with Skoda 8Tr and 9Tr vehicles with average age of 15 years. Even greater problem was the total lack of articulated trolleybuses, in Eberswalde in 1985 still existe the trailer pulling trolleybus-trains in everyday service. Because of the bad conditions, in Zwickau the local trolleybus service was already stopped in 1979. The situation of the Weimar and Potsdam networks were no better. In this circumstances arrived the first Ganz prototype to the Leipzig exhibition and to Weimar. There the trial runs were succesful, but because of the usage of western equippment in the electronics (which would have cost to the country to spend from the tight western currency) East-Germany was not able to order such vehicles.

Meanwhile the Ganz factory has altered the original equippment, and was able to replace the western parts to the cheaper eastern ones. Also the petrol-aggregate was omitted meaning significant reduction of the price of the trolleybuses. Then East-Germany decided to order 150 IK-280.93 type trolleybuses, of which the first series were delivered in 1985, the second in 1989. The first series was fitted with folding doors, but the second already with flapping doors, which was still at the time unusual in the country. A speciality of these trolleybuses was that they were able to run on every polarity of the poles, which was not the property of the rest of the GVMs.

After the launching of the modernisation programme, three new trolleybus network was built based on the new Ikaruses and Skodas: in Suhl, Hoyerswerda and in Stendal. Because of the central distribution of the new vehicles, some GVMs were moved to another city in few years.

After the german reunification, the high-floor Ikaruses were not suitable for the stricter European norms. From the originally ordered 150 vehicles, only 55 were delivered. Although at most of the cities the GVMs made a good impression, in the '90s they were doomed to be sold or scrapped. The last of the GVMs were in service in Germany in the town of Eberswalde (the 022 and 025, which were sold then to Szeged, Hungary, with the fleet number 507-506). Meanwhile other East-European countries selected some spare trolleybuses, which were still in good condition. This way the cities of Timisoara (Roumania), Tallin (Estonia), Chelyabinsk (Russia) and finally Szeged (Hungary) obtained GVM trolleybuses.

More about the East-German trolleybuses can

be found here.

About Eberswalde GVMs

one can read on these pages.

Fleet data

In Bulgaria, the capitol city Sofia ibought between 1985-91 alltogether 156 (?) GVMs. Also the town Wratsa purchased four articulated vehicles from Ganz. The bulgarian version obtained the type IK-280.92, but the differences and fleet data are unknown to me.Ganz trolleybuses in Bulgaria (IK-280.92)

|

|

||

|

|

|

||

|

|||

After the Budapest 600 solo trolleybus, in the '80s another solo IK-260 trolleybus was produced. This was fitted with the experimental electronics of the Ganz works. The trolleybus was finished in 1986, and in this year it was exhibited at Leipzig International Fair (East-Germany).IK-260 solo GVM trolleybus (IK-260.T2)

Some technical data:This trolleybus was equipped with the parts of the articulated trolleybuses, thanks to the equal power of the motors, this vehicle was able to accelerate even swifter. Also similarly to the german GVM versions, it was able to run on each polarity.

length: 11000 mm motor type: TK 110-K width: 2500 mm output: 196 kW height (with trolleys): 3520 mm seats: 22 weight (without load): 10120 kg standing places: 86

After exhibition the trolleybus was on trial run in Weimar, where it was bought in the end. There it obtained first the fleet number 8012, then 241. the car was extremely popular amongst the drivers. Meantime East-Germany ordered 12 similar solo trolleybuses for the city of Potsdam with delivery set to 1991, but after the unification the business was cancelled. The unique trolleybus remained in service until 1992, then it was taken back to Budapest by an agent. Here - since nobody wanted to buy it - it was dismantled.

Further informations of this trolleybus can be found on

the inofficial site of Ganz.

Another demonstration trolleybus was made for the Sowiet Union in 1987. This car made a short trial uns in Budapest, then it was in service with the fleet number 0010 in Moscow. The trolleybus was not long there, after it returned to Budapest. Finally its empty body was set aside at Pongrác depot; the Obus Ltd. was thinking about refurbishing it similarly to the DKV 400. Because of the bad condition of the vehicle, it was rather taken apart.The Moscow 0010 GVM prototype

In Budapest, the first trolleybuses from the GVMs were bought in 1987, after already it was produced in larger quantity to East-Germany and Bulgaria. These cars replaced the earlier 100 series and some part of the ZIU-9 type trolleybuses.The GVMs of Budapest: the 200ers.

Purcase of the GVMsThe first seven troleybuses had still folding doors, while the rest was supplied with flapping doors uniformly. After the year 2002, the first ones also obtain flapping doors itogether with the necessary reparation works. Today all 84 pieces are in service, there was no scrapping from the already 15 years old fleet. They run currently everywhere the 100ers ran before, today (2002) on lines 72, 75, 77, 79, 81, 82, 83 (except particular cases).

year 1987. 1988. 1989. 1996. number of new trolleybuses 7 26 50 1 fleet number 200-206 207-232 233-282 283

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical description of the GVMs

length: 16.5 m constant output: 196 kW weight (full load): 23850 kg auxiliary motor output: 12 kW seats: 35 acceleration: 1.3 m/s2 standing places: 110 deceleration with rheostatic brake: 1.2 m/s2 motor type: TK 110 K deceleration with pneumatic brake: 5 m/s2 The structure of the IK-280 trolleybus

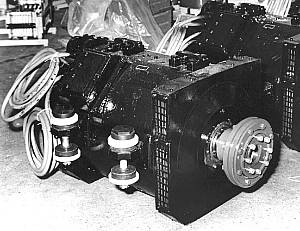

| The GVM trolleybuses were built in Ikarus body, which is similar to

the autobuses. The body is self-carrying, their side walls, roof, roof,

windows and doors are all play important role in the stability.

The motor, and the electric equippment is fitted on the cassis, the trolleys, some electronic filters and the brake-resistors are on the roof. The ventillation of the chopper electronics is through a typical side gap on the left side. |

|

| The trolleybuses are equipped with hydraulic servo for the steering,

which directs the A axle. The B axle is the driven one with double wheels,

the largest weight is here. The C acle is on the trailer part, this is

also steered proportionally to the bend of the articulation. This gives

an excellent steering property to the vehicle, where a solocar can turn,

the GVM can pass too.

The car has pneumatic suspension, which gives similar attribute of the running at every load. This makes the driver's job easier, comparing to the ZIUs the derailment of the trolleys are more unlike caused by road irregularities. Some trolleybuses are also equipped with a probe on the level regulation of the suspension, which is used to measure the actual number of passengers. These are called "Knorr"-cars (after the mark of the device). |

|

| Inside originally the GVMs were fitted with leather seats similar to

the last series of the IK-280 autobuses. With renewal works they were changed

to textile covered ones, also using digital informational instruments.

As interior lights strip lighting was installed.

The doors are pneumatic. The refurbished cars already cannot start with open doors, it is blocked electronically. The windows are also standard Ikarus design, amongst them roof vents are exchanging the air inside. The trolleybuses have automatic trolley pulling device, which in case of derailment, a spiral arrangement whips off the the trolley. This works good, the only disadvanage is the extra time to put back the trolley on the pole, since the device has to be wound again by hand. |

|

The GVMs were the first series of vehicle by the Budapest Transportation Company (BKV), which was equipped with (at his time) modern DC-copper electronics. This was consisted of conventional thyristors, made partially in Czechoslowakia and ths Sowiet Union. From a certain point the russian ones were replaced with western, after the running short of the stockpile.The electronic equippment of the GVM trolleybuses

| The great advantage of the GVMs were the excellent rheostatic brake

with very high recuperation rate; in this sense even the western types

are hardly competing with it. This was developped in the first part ogf

the '80s, modifying the original plans from the prtotypes. Some other construction

of the time even avoided rheostatic brake with the chopper, using Eddy-curent

brake instead.

The trolleybuses have motor TK 110 K with the power of 196 kW. The DC-motors with chopper electronics are slightly different from the ones used with resistor controls, having different type of character diagrams. |

|

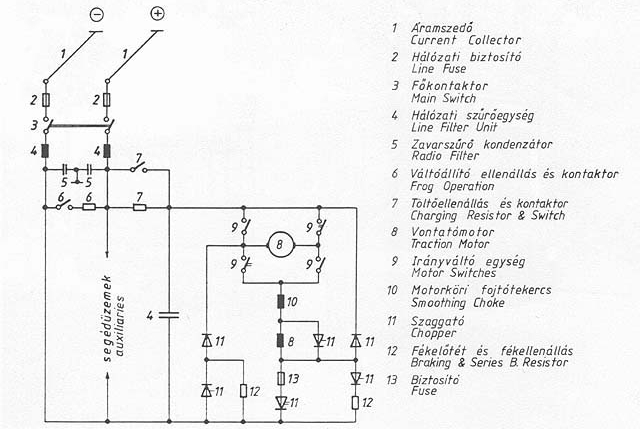

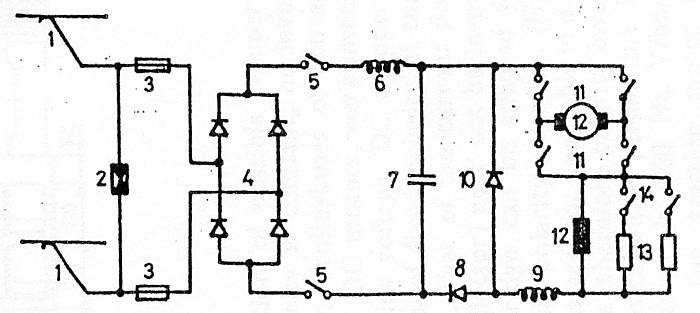

The simplified electric circuit of the GVM:

|

|

On the left are the protecting and filtering devices, together with the auxiliaries. The important electronic side is on the right. |

Here follows the main part of the circuit

|

|

In acceleration the chopper has only one task: to comvert the 600 V DC to a smaller mean value voltage. This is achieved by dense turning on-off the current, this way "chops" the chopper. Regulating the time ratio of the turned on and turned off state one can change the average level of the voltage. The frequency of the coupling is 500 Hz, but in case of too low or too high secodary voltage (in the case when the turned on or the turned off state would be too short) the frequency is dropped to around 70 Hz.Working in acceleration:

| The electronics is regulated with an analog computer. This means, that

the adjusment of some accelerating parameters is only possible throug replacing

some parts of the electronics (so - unlike the more modern types - it is

impossible basically to change them).

The GVMs have a jerk restriction: by turning on the power the GVMs are calibrated to 0.8 m/s3; by turning off 8 m/s3 secondary acceleration value. |

|

The electronics does two phase in one period.Rheostatic brake:

As on every trolleybus, the main brake is the pneumatic brake. This is regulated with the brake pedal; together with the rheostatic brake. Until the half way of the pedal, the rheostatic brake porvides maximal 1.2 m/s2 deceleration. With further pressing of the pedal, one decreases back the rheostatic brake giving way for the pneumatic brake, with achiving 5 m/s2 deceleration. In case of winter conditions, the rehaostatic brake can be shutted off.Pneumatic brake:

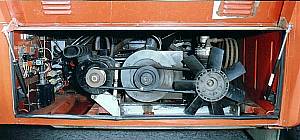

Auxilliaries:

| The compressor, the oil-pump of the steering servo and the generator

is driven from a common motor of 12 W output ran by 600 V. One has to admit,

that this is the most voulnerable part of the GVM's, it is noisy and it

brakes down very often especially in the summer heat. This is mainly bacause

it operates continuously, and can rech high temperature like that.

The vehicles were fitted with heating system with built in ventillator, it is situated under a seat in the passengers' room. |

|

| The direction of the trolleybus is exchanged with four contactors (wich

according to the above plan take part in deceleration

too).

As we can notice, the electronics is not suitable to operate in case of exchanged polarty. Moreover, the false polarty threatens the electronics, some places the electrolit condensators might blow up in this case. Though these are protected by fuses, but in the beginning the fuses could not react safely in time to avert the damage. |

|

Interesting fact was, that by the order of the first trolleybuses at the BKV, the directory has signed the contract, that on the Budapest network, there is no place where the trolleybuses run on opposite polarty. This was thought to be so, but during the testruns of the GVMs to Bulgaria at some place the trolleybuses misteriously always broke down. Namely at certain blunt angle crossings for a short section (a few 10 cm) the polarity exchanges(!). The vehicle could come through, if everything was shut down, but the most cases it produced malfunctions. After the nature of the problem was discovered, for a few years the engeneers debated to build in a polarity protection, but in the end they rather insulated both directions of such crossings.

However above the polarity exchanges, some more delicate points remained in the network: where the short no-voltage sections are not caused by an insulation, but only the two poles are in the same voltage (i.e. unidirectionally insulated trolleybus crossings, tramline crossings, points). In this cases the recuperational brake could cause sudden problem, when the trolleybuis tries to recuperate in a short-circuit (this is equivalent of having the two poles on the same voltage). In this case using the "no point-operating" switch, the driver can separate the circuit of the trolleybus completely from the poles, without the possibility of automatic shutdown of the electronics.

| Further problems occured in the winter conditions with new new copper electronics trolleybuses. Especially in case of sleet the ice can freeze on the pole. Thus the contact of the pole can go wrong. Wirh the ZIUs electrics this meant no great problem, only the trolleybus can start with jerks and great sparks. The GVMs sophisticated electronics is more sensible to such fluctuation of the voltage. In such conditions extra trolleybuses are sent to break the ice from the poles (naturally ZIUs); a former autobus (ex BU 88-41) was converted to a pole-sprinkling car; and the refurbished GVMs are supplied with a ice melting switch. |

In the rear section an extra resistor is placed to make possible to operate the points. |

A Ganz prototype circuit on a simplified plan:

|

|

1 - trolley, 2 - overvoltage limiter, 3 - main fuse, 4 - polarity reversing input rectifier, 5 - main contactor, 6 - filter choke, 7 - filter capacitor, 8 - DC chopper, 9 - smoothing choke, 10 -free-wheeling diode, 11 - reversing switch, 12 - traction motor, 13 - fiels weakening resistor, 14 - field weakening contactor |

The electric (rheostatic) brake is completely missing,

this is the main reason why was enough one chopper unit, compare to the

GVMs four.